Spirit A350 Flex Track Driller With Fastening Technology

To join the upper and forward lower shell (Section 15) composite fuselage panels of the Airbus A350 XWB aircraft, Spirit contracted AIT to develop the world’s first automated Flex Track driller with fastening technology.

Our driller/fastener is able to precisely drill, countersink, feed the fastener, apply sealant, and install the fastener at the point of use, reducing the manual labor involved in previous technology generations while also improving hole quality.

AIT’s driller/fastener is installed at Spirit’s Saint-Nazaire, France, facility to join the Section 15 panels, whose carbon fiber frame measures 65 feet in length and 20 feet in width.

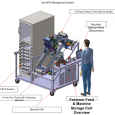

Key Features:

- 1st production Flex Track with full-size fastening machine to be developed and implemented

- Programmable 4th axis

- Programmed in “World/Airplane” coordinates (not a flat pattern as was typical with previous Flex Track systems)

- Collar is installed by an operator on the opposite side of the skin

- Used on CFRP/Alum Structures – could be easily adapted to CFRP/Alum/Ti structures

- Single-Pass Drill, Countersink, Seal and Install 3/16”, 7/32” & ¼” Diameter Hi-Loks & Lockbolts with Grips up to 9/16” long

- Utilizes Standard, Production Proven GEMCOR Fastener Installation Tooling

– (Anvils, Injectors)

– GEMCOR Manual Drop Station

- Integrated F2C2 Cassette Feeding and Loading System

- Balluf RFID Tool Management system

– Read and Write capability

- Machine Weight: 180 kg

- Programmable speeds 0-6000 RPM

– Also available in 10,000 RPM option

- Programmable clamp force up to 1400 N

- HSK32C Tribos Tool Holder

- Integrated Machine Vision system

Advanced Integration Technology > Projects > Drilling Projects > Spirit A350 Flex Track Driller With Fastening Technology

Advanced Integration Technology > Projects > Drilling Projects > Spirit A350 Flex Track Driller With Fastening Technology